Amazing COCONUT Processing in Factory Coconut Oil,

10/10/2017#0183;#32;0:00 Coconut processing factory, water and oil;9:11 Chocolate processing factory, chocolate art;More amazing videos:Automatic CAKE Processing Machines: https...

WhatsApp)

WhatsApp)

10/10/2017#0183;#32;0:00 Coconut processing factory, water and oil;9:11 Chocolate processing factory, chocolate art;More amazing videos:Automatic CAKE Processing Machines: https...

Aug 04, 2018#0183;#32;Coconut milk production. Coconut milk is the white liquid extract from coconut meat (endosperm). Coconut milk is a rich source of carbohydrate, protein, saturated fat (Lauric acid), manganese, phosphorus, iron, magnesium, potassium, vitamin C,

Flow chart of the production chain of coconut oil products for food application in the EU (1) Cultivation of coconuts (2) Drying of copra at primary production Coconuts Dried copra (3) Pressing of copra Crude coconut oil (A) Transport Storage (D) Transport by ocean going vessel Storage and transport of copra

Coconut milk and cream is a white, opaque proteinoilwater emulsion used in many traditional Asian cuisines. It is a milky fluid obtained by manually or mechanically extracting fresh kernel. The quality attributes are affected by many factors, such as the variety of nuts, water quality and volume used for coconut milk extraction. Due to its high oil content, coconut milk products are highly

6/10/2020#0183;#32;In 2018, global coconut production amounted to about million metric tons. Coconut production additional information Commonly referred to as the tree of life, the coconut has a wide

21/9/2017#0183;#32;Coconut Oil Production Flow Chart. Coconuts are fed into the dehusking machine. The machine removes the entire husk on the coconut. Husk can also be removed manually but you need more labor to finish this task. Coconuts must be deshelled and this should be managed without breaking the kernel. The deshelled kernels are passed through paring machine to remove brown testa/skin of

Coconut Milk products are prepared using a significant amount of comminuted coconut meat and expelled, where most filterable fibers and residues are excluded, with or without coconut water, and/or with additional water, thermally processed appropriately and sealed in a container to prevent spoilage. Product Styles 1. Light Coconut Milk The product obtained from either the bottom portion of

Coconut water is also considered a byproduct of desiccated coconut or coconut milk production, where the mature coconuts are collected and halved. As consumers increasingly demand the best quality coconut water, manufacturers prefer to drill the mature coconuts instead. This drains the coconut water out by minimizing the contamination of coconut water from the loose soil and fibres from the

14/10/1999#0183;#32;The average annual production of coconut during was estimated to be 50 billion nuts, or 10 million metric tons of copra equivalents. (APCC 1996, Table 2). Of the world production of coconut, more than 50 percent is processed into copra. While a small portion is converted into desiccated coconut and other edible kernel products, the rest is consumed as fresh nuts. The coconut

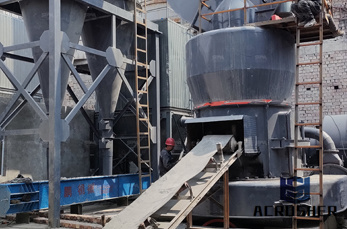

If youre thinking to start an own Coconut Oil Production Plant and invest in Coconut Oil manufacturing business, don hesitate to contact us for free guidance. We help you setting up a complete copra oil mill plant, also can offer a turnkey project plan, including factory layout design, equipments manufacturing, onsite plant installation and

production chart for coconut mill production chart for coconut mill. Dairy Ingredient List for Shopping Dairy Free. Here it is Our handy guide to identifying milk ingredients on food labels, from the obvious to the downright obscure! The list below is from my book, Go Dairy Free: The Guide and Cookbook for Milk Allergies, Lactose Intolerance, and CaseinFree Living

Coconut Milk amp; Coconut Cream B Coconut Oil C Coconut Flour D Creamed Coconut E. GRINDING Coconut ByProducts Manufacturing Flow Diagram BLANCHING DRYING SEPARATING amp; CLASSIFYING In case of production with SO2, metabisulfite is added /sprayed with pure fresh water . CT magnet FLAKE SHRED CHIP. GRINDING Coconut ByProducts

The processing of canned coconut milk starts with the extraction of coconut milk, followed by heating at 92 to 95 #176;C for 5 to 20 min. Emulsifiers and/or stabilizers are added before homogenization. The homogenized coconut milk is either hotfilled in cans or passed through an exhauster before can sealing. Since coconut milk (pH 6) is considered a lowacid food, it is necessary that the

If youre thinking to start an own Coconut Oil Production Plant and invest in Coconut Oil manufacturing business, don hesitate to contact us for free guidance. We help you setting up a complete copra oil mill plant, also can offer a turnkey project plan, including factory layout design, equipments manufacturing, onsite plant installation and commissioning, and operation training.

WhatsApp)

WhatsApp)