mesh ball mill, mesh ball mill Suppliers and Manufacturers

offers 957 mesh ball mill products. About 68% of these are Mine Mill, 11% are Grinding Equipment. A wide variety of mesh ball mill options are available to you,

WhatsApp)

WhatsApp)

offers 957 mesh ball mill products. About 68% of these are Mine Mill, 11% are Grinding Equipment. A wide variety of mesh ball mill options are available to you,

Particle size distribution influences the physical and chemical properties of solids. Therefore this criterion is of highest importance in the context of science and quality control. Only if the size distribution remains constant, a steady product quality can be guaranteed, as the following examples show:

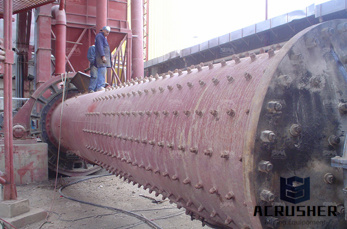

With more than 100 years of experience in ball mill technology, Metsos ball mills are designed for long life and minimum maintenance. They grind ores and other materials typically to 35 mesh or finer in a variety of applications, both in open or closed circuits.

Here is a convertible laboratory ore grinding mill. Use it as a Lab Ball Mill if you like overgrinding or a Rod Mill if you prefer selective milling. Sizes 8 x 8 to 8 x 16 (ball and rod) Extra Large Batch 12 x 15 (10 kilo ore load) Mild steel construction. Cantilever design.

Ball mills can grind in either a wet or a dry environment. In addition to the traditional rotatingdrum type, some models use planetary, vibrational or centrifugal motion. How to choose. Choice of ball mill will depend on the type and quantity of product to be ground.

Here is the old AllisChalmers Bond Work Index Grindability Test Procedure. The standard feed is prepared by stage crushing to all passing a 6 mesh sieve, but finer feed can be used when necessary. It is screen analyzed and packed by shaking in a 1000cc graduated cylinder, and the weight of 700 cc is placed in the mill and ground dry at 250 per cent circulating load. The mill is 12 in. x 12

Ball Mill, Ball Mill Classifying Production Line, CaCO3 Grinding Mill manufacturer / supplier in China, offering 2~10um Heavy Calcium Carbonate Production Line, Barite Powder Grinding Air Jet Mill for 245microns Ultrafine Grinding, Ultrafine 5000 Mesh Air Classifier Automatic Mill Air Classifier Mill

#0183;#32;Dry batch milling tests were performed in a laboratory scale ball mill measuring by cm. The mill specifications are given in Table 1. A constant ball load of 20% was maintained in all the tests with a ratio of for binary and for trinary ball mix. Table 1.

The ball mill work index laboratory test is conducted by grinding an ore sample prepared to 100 passing mm (6 mesh) to product size in the range of 45150 #181;m (325100 mesh) thus determining the ball mill work index (Wi B or BWi).

Ball mill classifier systems have been improved over time and are now capable of achieving much finer products. In the past, a particle size with a D97 of 10 microns was only possible. Now particle sizes down to a D97 of less than microns can be achieved, with a D50 in the range of microns.

#0183;#32;T 80 = transfer size from SAG mill to ball mill. or the SAG mill product P 80, in millimetre. It is claimed that this equation is applicable to any SAG product size and includes fine grinding beyond 10 mesh ( mm) product size. The correlation was good for four of the five SAG mills studied.

The standard bond ball mill grindability test determines the ore grindability g rev1 and work index on an ore which gives the ball mill power consumption. for the next cycle is determined after screening out and weighing the undersize fraction from a screen of a mesh the same size as the intended product passing size.

Metallurgical ContentBall Mill Capacity VS Rod Mill CapacityWorking Principle amp; OperationRod Mill Capacity TableBall VS Rod Mill ConversionTypes of Mill DischargeBall Mill Trunnion and Mill Grate DischargePeripheral Grinding Mill DischargeLoad Capacity of Trunnion BearingsBall Mill amp; Rod Mill LinersGrinding Mill GearsGrinding Mill DrivesBall Mill Grinding CircuitBall Mill SpecificationsAll

Ball/Rod mill Literature . The Ball/Rod mills are meant for producing fine particle size reduction through attrition and compressive forces at the grain size level. They are the most effective laboratory mills for batchwise, rapid grinding of mediumhard to very hard samples down to finest particle sizes.

mesh size control ball mill. Mineral grinding fine output size 200mesh for south Africa gold ball mill See larger image Product Detail Company Profile Report Suspicious Activity Quick...

offers 158 200 mesh ball mill products. About 13% of these are Mine Mill, 12% are Grinding Equipment. A wide variety of 200 mesh ball mill options are available to you, such as condition, local service location, and applicable industries.

Hundreds of ball mills the product fineness and grain size distribution are adjusted via the peripheral material discharge. In case of circuit grinding, these parameters are set with the high efficiency the product fineness can be preselected by providing a specific mesh width on the screening machine. Technical data; Throughput rate:

How To Get 90 Mesh In Ball Mill Used. We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment.

WhatsApp)

WhatsApp)