Vertical Roller Mill Structure And Working Principle

LM Vertical Roller Mill Product features: Integration of multiple functions, more stable and reliable. Feed particle size: 070mm; Production capacity: 3340 tons / hour

WhatsApp)

WhatsApp)

LM Vertical Roller Mill Product features: Integration of multiple functions, more stable and reliable. Feed particle size: 070mm; Production capacity: 3340 tons / hour

Operation. Material grinding process motor through reducer rotating drive disc, the material falls from the mill under the central entrance and exit, under the action of centrifugal force to the disc edge by the roller to move and the crushing, grinding out lap after the material was speed up the flow to and vertical mill with one of the separator, after the meal by the separator back to the

20/06/2018#0183;#32;Vertical roller mill is an important production equipment for fine powder, which will be damaged in various kinds of graphite production lines. In order to make the equipment work better, we will introduce the vertical roller mill in graphite production line Operation and maintenance measures to ensure that equipment for production projects bring greater productivity.

JET Vertical Milling Machines JET Vertical Milling Machines are durable enough to be the workhourses of your operation and come with addons and features that give you . vertical mill and ball mill operation rkcnmh More information of tube and vertical mills .

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a work piece. This may be done varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavyduty gang milling operations.

News. LM Vertical Grinding Mill For Limestone. There are mainly three types in LM vertical grinding mill: the K series, the M series and the N series.

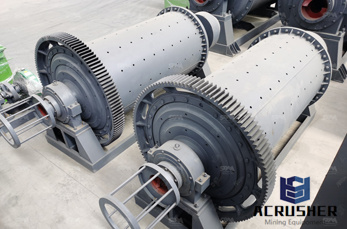

Improving knowledge of grinding technology and mill operations to operate, optimise and troubleshoot ball mill and vertical roller mill grinding installations. Ball mills and vertical roller mills are used for many grinding applications in cement production: raw meal

Mill Machining, Milling Process, Horizontal amp; Vertical Milling Machines Definition. Milling is a process performed with a machine in which the cutters rotate to remove the material from the work piece present in the direction of the angle with the tool axis. With the help of the milling machines one can perform many operations and functions starting from small objects to large ones.

06/07/2019#0183;#32;This is Mill Skills, a multipart series to help you learn basic machine shop work. Exclusive videos, drawings, models amp; plans available on Patreon! https://...

End milling operation produces flat vertical surfaces, flat horizontal surfaces, and other flat surfaces making an angle from table surface using milling cutter named as an end mill. This operation is preferably carried out on a vertical milling machine. End Milling Operations . 8) Profile milling. Fig. illustrates profile milling operation. It is the operation of reproduction of an outline of

Vertical roller mill operation. Since the vertical roller mill tensioning device is packing system, oil tanks are not automatically inferior vena flow, after all the mill shut down or in the repair process, for the framework to enhance or decrease the pressure required to do the following:

When the vertical mill is in normal operation, the vibration value of the mill shall be strictly controlled within a reasonable range and shall not exceed /s for an feeding amount of the vertical mill must be adapted to the capacity of the vertical mill. When the material is fragile, good, low hardness, high tension force, there may be a moment of air pressure may cause

03/09/2020#0183;#32;The end milling is the operation of producing a flat surface which may be vertical, horizontal or at an angle in reference to the table surface. The cutter used is an end mill. The end milling cutters are also used for the production of slots, grooves or keyways. A vertical milling machine is more suitable for end milling operation. 10. Saw Milling

For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and maintenance, energy efficiency and product quality. Further, our vertical roller mill solution for cement grinding has an ability to dry, grind and separate within a single

#0183;#32;The ramtype mill has its cutting head mounted on a ram that can slide backandforth. This increases the tool movement to 2 axes X and Y. Both horizontal and vertical options of the ram mill are available on the market. Many of such mills also include the ability for swivelling the cutting head. Planertype mill

12/10/2019#0183;#32;This is Mill Skills, a multipart series to help you learn basic machine shop work. Exclusive videos, drawings, models amp; plans available on Patreon! https://...

LM Vertical Roller Mill Product features: Integration of multiple functions, more stable and reliable. Feed particle size: 070mm ; Production capacity: 3340 tons / hour; Applicable materials: Limestone, calcite, dolomite, petroleum coal, gypsum, barite, marble, talc, coal powder, etc. Online Chat. WORKING PRINCIPLE. The motor drives the grinding table through decelerator. The materials fall

WhatsApp)

WhatsApp)