Online Course: Ball Mill cement grinding systems YouTube

#0183;#32;FL has designed a series of online training for the cement industry, providing you with easy and instant access to our specialised technical training.

WhatsApp)

WhatsApp)

#0183;#32;FL has designed a series of online training for the cement industry, providing you with easy and instant access to our specialised technical training.

Cement grinding with our highly efficient ball mill An inefficient ball mill is a major expense and could even cost you product quality. The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and low maintenance.

MRD/MRE ball mill; SLV high efficiency and market entrants as well as for large construction companies aiming to expand their position by manufacturing cement on the spot. The ingenious design allows the ready2grind plant to be transported and mounted fast and The grinding process is the same as that of bigger Pfeiffer grinding plants.

HOLTEC has undertaken Performance Optimisation of the cement grinding circuits by doing process diagnostic studies in many cement plants. The paper describes the approach for the process diagnostic study for the optimisation of a ball mill circuit and is supported with typical case study done by HOLTEC in a mio t/a cement plant.

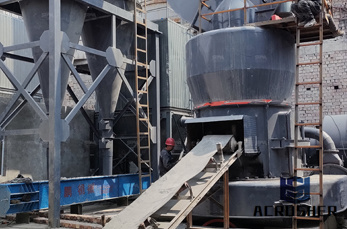

Raymond Mill, Ball mill, Vertical Roller Mill, Cement Mill, MXB erection loesche erection steps of vertical mill in cement plant Zenith. cement ball mill erection YouTube. May 6, 2014 wash plant Grinding Mill China silica sand for filtration pdf ball mill erection procedures pdf 12 Feb 2014 Fls Cement Ball Mill Erection Process Group

#0183;#32; Ball mill is an efficient tool for grinding many materials into fine powder. The Ball Mill is used to grind many ki...

The ball mill is a grinding machine which is often used for cement grinding and raw meal preparation in cement plants The grinding media is the most important part of a ball millWhen facing different production needs we must properly choose the type loading capacity grading and filling rate of grinding media to make the ball mill achieve the optimal production efficiency.

Overview. The ball mill for clinker is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other industries to grind all kinds of ores.

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum chunk size, product size as P80 and maximum and finally the type of circuit open/closed

Ball Mill Close Circuits Ball Mill And Open Circuits . Ball Mill We bring forth a highly advanced Ball Mill specifically engineered for both wet as well as dry cement grinding applications Classified depending on the circuit design bearing grinding type and drive the selection is made on the basis of the product fineness quality and nature of raw material site conditions and specific requirements.

Ball Mill Grinding Media Calculation Detoxsynergy. Ball mill media charge calculation. Ball mill charge calculation in cement ball mill grinding media calculation the ball charge mill consists handbook for dry process plants pdf 187 learn more technical notes 8 grinding r p king media or charge in the mill and dm is the diameter of e is a f.

Cement Ball Mill Building Procedure Cement grinding vertical roller mills versus ball to operate a ball mill of cement cement ball mill building procedure procedures for cement mill ballmill design pochirajucoin cement mill notebook free download as pdf file pdf text file txt or read online for free 71 heat generation in tube mills 72 cooling procedures during the

Cement Ball Mill JXSC Machine. What is the cement ball mill The cement ball mill is mainly used for grinding the finished products and raw materials of cement plants, and is also suitable for grinding various ore and other grindable materials in industrial and mining enterprises such as metallurgy, chemical industry, and electric power.

The ball mill is traditionally the basic system used for the grinding of raw material, clinker and additives in a cement plant, as well as a wide range of minerals. Benefiting from a large experience, the FCB BMill has been designed to be particularly well adapted for the grinding of products at high fineness and grinding of very abrasive products and solid fuels.

cement plant grinding mills parameters Popular Education. cement from cement clinker consist of twocompartment tube mills and the air . The work horse of the cement grinding plant is the twocompartment ball mill, Effect of the classifier design and operational parameters on

Port Kembla Cement Grinding Mill EXODUS Mining machine. Miningport Kembla Grinding Mill. Site tour members and friends of engineers australia you are invited to attend a site tour of the port kembla cement grinding plant in 2011 cement australia pty ltd and ecocem pty ltd entered into a joint venture to construct a new facility the port kembla grinding mill which will produce cement and

WhatsApp)

WhatsApp)