ANALISIS PROSES PEMESINAN UP MILLING DAN DOWN

Text RAMA_21201___01_front_ Accepted Version Available under License Creative Commons Public Domain Dedication. Download (1MB

WhatsApp)

WhatsApp)

Text RAMA_21201___01_front_ Accepted Version Available under License Creative Commons Public Domain Dedication. Download (1MB

07/03/2018#0183;#32;Up milling vs Down milling, milling methods, up milling and down milling operation, difference between up milling and down milling,up milling vs down millin...

Climb Milling = Down Milling; Conventional Milling = Up Miling; Climb milling is when the direction of cut and rotation of the cutter combine to try to suck the mill up over (hence its called climb milling) or away from the work. It produces the best surface finish.

Up Milling: Down Milling: 1. In up milling the cutter rotates against direction of feed. In Down milling, the cutter rotates with direction of feed. 2. It is also known as conventional milling. It is also known as climb milling. 3. In this, chip width size is zero at initial cut and increase with

Pengaruh proses pemesinan up milling dan down milling terhadap kekasaran permukaan pada pemotongan ban aluminium 6061 oleh: Romadhon, Nuzulul Rmad Terbitan: (2017) Pengaruh jenis proses pemotongan pada mesin milling terhadap getarandan kekasaran permukaan dengan material aluminium 6061 oleh: RETYAWAN, Okky Nugra Terbitan: (2015)

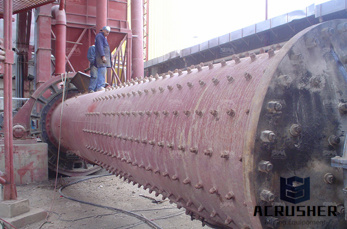

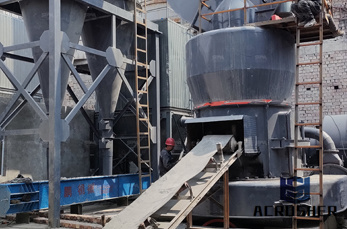

24/06/2014#0183;#32;1. Definisi milling ( frais ) proses milling adal suatu proses permesinan yang pada umumnya menghasilkan bentukan bidang datar ( bidang datar ini terbentuk karena pergerakan dari meja mesin) dimana proses pengurangan material benda kerja terjadi karena adanya kontak antara alat potong yang berputar pada spindle dengan benda kerja yang tercekam pada meja mesin.

Penelitian ini bertujuan menganalisis perbandingan proses milling antara up milling dan down milling hasil dari helical interpolation cutting. Spesimen yang digunakan yaitu baja karbon sedang dengan dimensi panjang 73 mm dan diameter #216; mm. Proses milling dilakukan dengan mesin CNC Agma A8 menggunakan pat End mill HSS 2 flute, dengan

up milling dan down milling. Up Milling Down Milling 1 This machine is also called as conventional milling This is called a climb down milling 2 The cutting forces act upward The cutting forces act downward 3 Mostly used for rough cutting operations This is used for finishing operations 4 Due to more tool wear rate the durability of the tool is less

In climb milling, the cutter has the tendency to push workpiece towards the table, so it is also called down milling. Tendency of holding down the workpiece reduces the cutting vibration. It has tendency to drag workpiece into cutter, so there is a safety issue. The chip during the cutting process leaves behind the cutter, which eases the chip removal. It possess longer tool life. This type of milling generally used for

MacamMacam Pisau Frais ~ materi SMK dan kuli #183; Gambar 9. (a)Frais naik (up milling) dan (b) frais turun (down milling). 1. Frais Naik (Up Milling) Frais naik biaa disebut frais konvensional (conventional milling). Gerak dari putaran pisau berlawanan ar terhadap

Difference Between Up Milling and Down Milling mech4study

WhatsApp)

WhatsApp)