Breakthrough technology turns coal plant CO2 into baking

At one coalfired power plant in southern India, Carbon Clean Solutions is capturing CO2 and turning it into baking powder for the first time at a largescale industrial operation.

WhatsApp)

WhatsApp)

At one coalfired power plant in southern India, Carbon Clean Solutions is capturing CO2 and turning it into baking powder for the first time at a largescale industrial operation.

Coal dust is a fine powdered form of coal, which is created by the crushing, grinding, or pulverizing of coal. Because of the brittle nature of coal, coal dust can be created during mining, transportation, or by mechanically handling is a form of fugitive dust.. Grinding coal to dust before combusting it improves the speed and efficiency of burning and makes the coal easier to handle.

Turning Dirty Coal into Clean Energy Today''s expensive gasoline is making people look for alternatives. That has opened doors of opportunity for entrepreneurs like Andrew Perlman, who

#0183;#32;This rock is then usually pulverized into a powder and then it is burned in a coal power plant. When coal is burned, there are tubes of water in the boiler and this water is heated and boils (see image below). When the water boils, it transforms into steam. The steam then turns a turbine attached to a generator and electricity is produced.

However, when made into briquettes, they have the same shape and length that look well and have higher price. How to make charcoal briquettes from charcoal dust? To make charcoal briquettes from waste charcoal powder, a set of charcoal briquetting machine is a must. You may also need to add certain amount of coal binder.

Turning Dirty Coal into Clean Energy Today''s expensive gasoline is making people look for alternatives. That has opened doors of opportunity for entrepreneurs like Andrew Perlman, who is betting

Coal dust Wikipedia

The machine make the coal waste into bars for further Request Quotation... used to convert oil and natural gas into electricity: A machine called a pulverizer grinds the coal into a fine powder. a machine that turns mechanical energy Request Quotation. grinding machine for

So it is essentially like turning CO2 back into a brown coal.quot; CO2 slowly converts into solid flakes of carbon as they detach from the liquid metal surface in this vial. (Torben Daeneke)

Coal is first milled to a fine powder, which increases the surface area and allows it to burn more quickly. In these pulverised coal combustion (PCC) systems, the powdered coal is blown into the combustion chamber of a boiler where it is burnt at high temperature (see diagram).

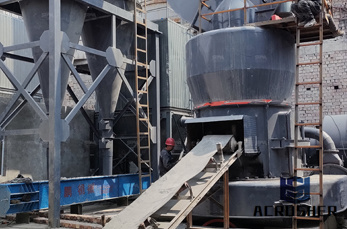

grinding machine used for convert coal into powder. Grinding coal into powder is what kind of change used coal for heating and later for cooking heat and pressure changed the plants into coal is similar to the process used to convert oil and natural gas into electricity 1 A machine called a pulverizer grinds the coal into a fine powder 2

#0183;#32;coal pellet mill is used to process different powder below 3 mm into pellets. The coal pellet machine can be used to press coal dust, coke powder, charcoal powder, carbon black powder

Charcoal briquette machine is a good assistant which helps you to treat the waste charcoal dust as a valuable source.. Why charcoal briquette. Charcoal briquette is widely used around the world for BBQ, fuel, etc. Its really a big deal that a lot of companies doing the charcoal making around the world when making the charcoal, there will be a lot of fine charcoal dust we need to collect and

Get access to industrialgrade egg powder making machine at for varied commercial drying uses. These egg powder making machine are sturdy and perform optimally saving energy bills.

#0183;#32;The conversion of coal begins in pulverized coal combustion systems, which start the process by steaming coal, which then turns into powder. In its powder form, coal is added to boiler combustion chambers, which heat the substance to high temperatures. This reaction produces hot gases and heat energy, which combine with water to form steam.

In 1768, John Wilkinson built a more practical oven for converting coal into coke. Wilkinson improved the process by building the coal heaps around a low central chimney built of loose bricks and with openings for the combustion gases to enter, resulting in a higher yield of better coke.

Coal quality: When using dry powder coal briquette making machine, you can choose bituminous coal which has certain cohesiveness and suitable for hot pressing (the maximum thickness of gelatine layer to be around 10mm) or the mixture of good cohesiveness bituminous coal (the maximum thickness of gelatine layer to be larger than 15mm) and anthracite, weakly caking coal and noncaking coal.

WhatsApp)

WhatsApp)