The Selection Design and Application of Mill Liners for

Mill Liner Handler gt; For large mills these are mandatory gt; Requires flat floor mill surrounds as a part of the design gt; Access and space to store liners. Retractable feed

WhatsApp)

WhatsApp)

Mill Liner Handler gt; For large mills these are mandatory gt; Requires flat floor mill surrounds as a part of the design gt; Access and space to store liners. Retractable feed

Sag mill liner handler 98m213 sag mill liner handler 98m213 me what is a mill liner handler a mill liner handler is a purpose designed machine used to remove and insert liners in grinding millsypically, rmes mill liner handlers find appliion in ag, sag, ball and rod mills throughout the hard rock mining regions of the price

Ball Mill Liner Handlers Nostalgie Deutschland. Mill liner handler in iran greenrevolutionorgin ball mill liner handler, maxitool liner handlers and mill the mclellan mill liner handler is an electric hydraulic powered machine that is designed to assist in replacing the worn shell liners in ba...

Mill Liner Handler gt; For large mills these are mandatory gt; Requires flat floor mill surrounds as a part of the design gt; Access and space to store applications as ball mill liners and grinding balls Typical microstructure of class 1 type D nickelchromium white cast iron.

Liners are placed by the liner handler operator alone and the bolts are inserted from the outside of the mill. Local support and global expertise At , cooperation with our customers and availability to offer support and service are of key importance.

ball mill liner handler, maxitool liner handlers and mill the mclellan mill liner handler is an electric / hydraulic powered machine that is designed to assist in replacing the worn shell liners in ball and sag type . Read more. mill liner handler.

Apr 03, 2019#0183;#32;The concept is suited for AG, SAG and ball mills. When changing conventional mill linings, a liner handler operator and a person with a bolt is needed inside the mill

Mill Relining Machines and Handlers. Delta Engineering is a designer and manufacturer of Mill Liner Handler Machines. Mill Liner Handling Machines have been developed for the placement and removal of the liners inside grinding mills. Mill Liner Handlers are typically positioned nearby to the ball, SAG or AG mill (s) they service.

Liner handler capacities are available up to 10000 pounds and larger FAST EASY SAFE RELINING Whether your grinding mill is a large ball or rod mill semiautogenous or autogenous you can reline your mill faster easier and safer with PaR Systems mill liner handlers PaR understands your mill

A longer lasting mill liner means less downtime for maintenance or new liner installation. A mill liner that occupies less space allows increased volume within the mill and leads to greater grinding capacity and throughput potential. Safer maintenance. 50% lighter and have 50% fewer parts on average when compared to traditional cast steel liners.

Various mill liner handlers have been advanced prior to this time, as well as other manipulating equipment. For example, the assignee of the present application has developed a mill liner handler that operates from outside of the mill. This is shown in Pat. No. 3,540,603, Issued Nov. 17, 1970.

McLellan Mill Liner Handlers and Cranes for the Mining Industry The McLellan mill liner handler is an electric / hydraulicpowered to assist in replacing the worn shell liners in ball and sag type grinding mills. . Click amp; Chat Now

RMEs RUSSELL 7 Mill Relining Machines feature liner lifting capacities from 1500kg to 7250kg and typically access the mill cavity from the mill feed end. These Mill Relining Machines are suitable for medium to large SAG, AG and Ball Mills. RUSSELL 7

Mill Liner Handler. Reliable, durable, and dependable construction allows for reliable service during critical, costly downtime. McLellan Designed Mill Liner Handlers are designed to be user friendly. Our main frame welded tubular steel chassis has mounting provisions for the moving of horizontal beam rollers, transpiration controls, hold down

McLellan Industries is the original designer of the Mill Liner Handler. Our experience and support are well known throughout the world. With over 50 years of research and development experience, we custom engineer and manufacture quality built equipment for Ball, Sag,

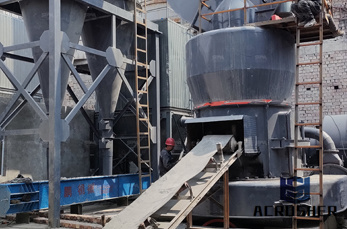

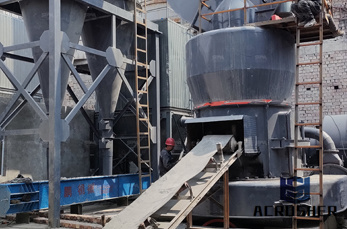

Raymond Mill. Adopting many advantages from various mills, and the ideal substitute of the Raymond Mill. READ MORE. Vertical Roller Mill. Automatic control system makes remote control, low noise, and integrate sealing device stop dust spill and pollute the environment. liner handler for ball mill .

Sep 10, 2014#0183;#32;McLellan mill relining systems deliver faster and safer mill liner installations.

Single wave liners are recommended for larger size balls (50mm/ and larger). The number of the lifters to the circle equals approximately D in meters (for D in feet, divide D by ). The liners are from 50 to 65 mm thick (2 to ) with the waves from 60 to 75 mm ( to 3) above the liners.

Manufacturing Machine liner Handler MEH1000 model for ball mill #216; 18 ''x '' long, with wristgrip. Capacity of 1,000 kgs. 2000. Client: Svedala (Cajar Ferro) Brazil. Machine Design and Manufacturing Handler Liners MEH1000 model for ball mill #216; 20 ''x '' long. Capacity 2000.

The MILLMAST Powershift is the inmill erected liner handler which suits small to medium mills with high ball charge levels. Erected in minutes and able to handle liners weighing up to 400kg, MILLMAST Powershift eliminates all manual liner lifting. Power is sourced from the MILLMAST Powerpack placed outside the mill.

Ball Mill Liner HandlerBall Mill. A new PolyMet shell liner concept has been developed by s Mill lining solutions. The new linings have been installed in two 38 AG mills, the largest mills . Ball Mill Liners Multotec. Ball Mill Liner components: Our ball mill liners solutions can be fitted with MultoMet composite lifter bars, shell plates

Ball Mill Liner Handlers Mine Equipments. Xingbang mining machine high quality ball mill,cement mill,rod mill cement, silicate, or dry ball mill3. overflow or grate ball grinder4. Motor connected to gearbox via a Vbelt drive. There are ladder liner and ripple liner and different all kinds of mining equipment, such as jaw crusher

WhatsApp)

WhatsApp)