Ball mills

Features Specifications Parts and services Customer cases. With more than 100 years of experience in ball mill technology, Metsos ball mills are designed for long life and minimum maintenance. They

WhatsApp)

WhatsApp)

Features Specifications Parts and services Customer cases. With more than 100 years of experience in ball mill technology, Metsos ball mills are designed for long life and minimum maintenance. They

The extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and therefore short grinding times. The PM 200 is a convenient bench top model with 2 grinding stations. You may also be interested in the High Energy Ball Mill Emax, an entirely new type of mill for high energy input. The unique combination of high friction and impact results in extremely fine particles within the

Miniature End Mills Ball Stub amp; Standard is Harvey Tool''s fully stocked, solid carbide, ball profile offering, including tools with cutter diameters as miniature as .002quot;. Choose from 2, 3, or 4 flute styles, and from uncoated, AlTiN coated, or Amorphous Diamond coatings.

Mar 10, 2020#0183;#32;How a Ball Mill Works. Ball mills work by using balls to grind materials. Materials such as iron ore, pain and ceramics are added to the ball mill. Next, the ball mill is activated so that it rotates either on its vertical or horizontal axis. As the ball

Features Specifications Parts and services Customer cases. With more than 100 years of experience in ball mill technology, Metsos ball mills are designed for long life and minimum maintenance. They grind ores and other materials typically to 35 mesh or finer in a

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium.

3 product ratings Ultima Chrome Billet Ball Mill Triple Trees Set Harley 41MM Wide Glide Softail. Buy It Now. Free shipping. Watch; 1/16quot; Dia x 1/8quot; Cut 4 Flute Double End BALL Carbide End Mill USA Made 5Pack C8. Brand New. 5% off 100+ Buy It Now. Free shipping. Watch; METAL REMOVAL Carbide Ball End Mill 6mm 2FL M30852.

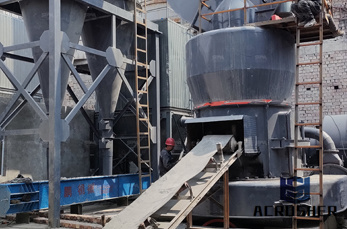

Ball Mill. Ball mill is widely used in the powder production lines, such as cement, silicate, refractory materials, chemical fertilizer, glass ceramics, etc. According to the need of customers, ball mills can realize both wet and dry production. Ball mills have been designed in standard sizes of the final products between mm and mm in

China''s most powerful ball mill equipment manufacturers the auspicious light machinery, professional production of ball mill, ball mills, ball mill machine and other products, advanced technology, reasonable price, the details please consult:

Nov 26, 2019#0183;#32;Ball mills are fine grinders, have horizontal ball mill and vertical ball mill, their cylinders are partially filled with steel balls, manganese balls, or ceramic balls. The material is ground to the required fineness by rotating the cylinder causing friction and impact.

Mixer Mills grind and homogenize small sample volumes quickly and efficiently by impact and friction. These ball mills are suitable for dry, wet and cryogenic grinding as well as for cell disruption for DNA/RNA recovery. Planetary Ball Mills meet and exceed all requirements for fast and reproducible grinding to analytical fineness. They are used for the most demanding tasks in the laboratory, from routine

Mineral Ball Mill. It usually adopts wet type ball mill in the mineral production. The grate and overflow type ball mills are the most universal equipment in the mineral plant. The grate type is usually used in the first segment of the two stages, or place of discharging the rough ore. Porcelain Lined Ball Mill. Peanut shells are byproducts of

The extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and therefore short grinding times. The PM 200 is a convenient bench top model with 2 grinding stations. You may also be interested in the High Energy Ball Mill Emax, an entirely new type of mill

The ball milling process is carried out for approximately 100150 h to obtain uniformsized fine powder. In highenergy ball milling, vacuum or a specific gaseous atmosphere is maintained inside the chamber. Highenergy mills are classified into attrition ball mills, planetary ball mills, vibrating ball mills, and lowenergy tumbling mills. In highenergy ball milling, formation of ceramic nanoreinforcement by in situ

OSCARBIDE Carbide End Mills CNC 1/8quot; Shank Ball Nose Milling Cutter Spiral Router Bits 2 Flutes End Mill for Engraving Milling 3D sculpturing Roughing Acrylic Wood PVC Aluminum 10pcs. out of 5 stars 36. Misc. 22. 99. 5% coupon applied at checkout Save 5% with coupon.

(1) Types on the Basis of Cylinder. 1. Short Cylinder Ball Mill: The ball mill with the cylinder length (L) less than 2 times of the cylinder diameter, the ball mill with L 2D is short cylinder ball mill, which is usually of single bin structure, mainly used for rough grinding or primary grinding operation, and can realize the wide use of 23 ball mills in series.

Cobalt Steel Ball End Millswith Two Milling Ends. With better heat and wear resistance than highspeed steel, these cobalt steel end mills can run at higher speeds and provide better performance on hard material, such as cast iron, hardened steel, titanium, and tool steel. When one end wears out, turn the tool around for a sharp edge.

WhatsApp)

WhatsApp)