Triboelectrostatic separation of unburned carbon from

Journal Article: Triboelectrostatic separation of unburned carbon from fly ash Title: Triboelectrostatic separation of unburned carbon from fly ash Full Record

WhatsApp)

WhatsApp)

Journal Article: Triboelectrostatic separation of unburned carbon from fly ash Title: Triboelectrostatic separation of unburned carbon from fly ash Full Record

Triboelectrostatic Separation of Fly Ash with Different Know More. A combination of mechanical sieving and triboelectrostatic separation were used to separate fly ash The results indicate that a simple separation of unburned carbon from fly ash is achievable at particle sizes of 74 and 44 microns Subsequently triboelectrostatic separations were conducted via a louvered plate separator The

An industrial fly ash sample was cleaned by three different processes, which were triboelectrostatic separation, ultrasonic column agglomeration, and column flotation, cleaned an industrial fly ash sample. The unburned carbon concentrates were collected at purities ranging up to 62% at recoveries of 62%.

While other researchers have used combustion techniques and flotation processes for LOI reduction of recovered landfilled and ponded fly ash, ST Equipment amp; Technologies (STET) has found that its unique triboelectrostatic belt separation system, long used for beneficiation of freshly generated fly ash, is also effective on recovered ash after suitable drying and deagglomeration.

10/11/2015#0183;#32;STET Triboelectrostatic separation has been used for the commercial beneficiation of coal combustion fly ash to produce a low carbon product for use as a cement replacement in concrete for nearly 20 years. Download PDF . F. Hrach, S. Gasiorowski, ST Equipment amp; Technologies LLC (STET), 101 Hampton Avenue, Needham MA 02494 USA

15/7/2019#0183;#32;The principle of triboelectrostatic separation of fly ash is shown in Fig. 5. There are differences in the electrical properties of unburned carbon and ash particles. As the particles pass through the friction device under air entrainment, friction is caused by collisions between particles and between particles and the friction device walls.

1/5/2001#0183;#32;Dry triboelectrostatic separations of fly ash derived from both coal combustion and the combustion of coal mixed with 10 wt% biomass were conducted. Two different types of triboelectrostatic separators parallel plate and louvered plate separators were used for this study.

1/6/1997#0183;#32;CONCLUSIONS This study has shown that dry triboelectrostatic separation of fly ash has the potential to separate unburnt carbon from fly ash. Laboratory tests on a simple parallelflow separator showed that 6080 wt% of the ash could be recovered having a carbon content lt; 5 wt%, and up to 50% of the carbon could be recovered as material with a carbon content gt; 50 wt%.

The dry triboelectrostatic separations of fly ash derived from both coal combustion and the combustion of coal mixed with 10 wt. % biomass were also performed. The triboelectrostatic separation of coal fly ash and 10 wt. % switch grass fly ash were conducted in the louvered plate

A combination of mechanical sieving and triboelectrostatic separation were used to separate fly ash. The results indicate that a simple separation of unburned carbon from fly ash is achievable at particle sizes of 74 and 44 microns. Subsequently, triboelectrostatic separations were conducted via a louvered plate separator. The results show that the final carbon content in the products, which

Separation of unburned carbon from coal fly ash: A review

triboelectrostatic or a wet agglomeration column technique Dry Separation of Fly Ash Triboelectrostatic beneficiation of fly ash to remove unburned carbon has been investigated recently [12] During triboelectrification, organic and mineral particles are charged with opposite polarity and separate d by using an electrostatic separator

Fly Ash Unburned Carbon Electrostatic Separation Tribocharging Faraday Cage Presented at the Int/Sym. on Chem. Eng. (Cheju, Feb. 810, 2001), dedicated to Prof. H. S. Chun on the occasion of his retirement from Korea University.

25/1/2007#0183;#32;A combination of mechanical sieving and triboelectrostatic separation were used to separate fly ash. The results indicate that a simple separation of unburned carbon from fly ash is achievable at particle sizes of 74 and 44 microns. Subsequently, triboelectrostatic separations were conducted via a louvered plate separator.

Triboelectrostatic Separation of Fly Ash with Different Charging Materials

Triboelectrostatic separation of fly ash Institute of Mining and Metallurgy . Experimental study on fine coal upgrading based on tribo To explore the triboelectrostatic Research and Experiment on Sulfur Removal and Ash Solutions for Reducing Carbon Concentration in Power Plant Fly Ash

has been considered for the separation of unburned carbon from fly ash into economically valuable products. Apart from these methods, froth flotation and air classification are also used for the separation of unburned carbon from fly ash. Some studies show that unburned carbon can be recovered with oil agglomeration process.

1/4/2002#0183;#32;Abstract. Triboelectrostatic separation has been investigated as a method for separating unburned carbon from coal combustion fly ash. It was found that when a fly ash is exposed to moisture before it undergoes separation, the charging properties of the components of the fly ash change significantly. The mineral and carbon components of the fly ash

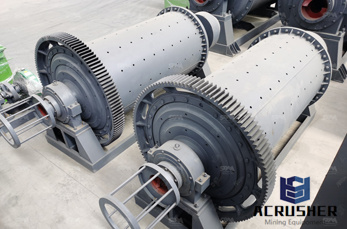

ST Equipment amp; Technology (STET) develops and manufactures Triboelectrostatic Separators that provide a high rate and completely dry beneficiation for pulverized coal fly ash. The STET separation process has been used commercially since 1995 for pulverized coal (PC) fly ash beneficiation and has generated over 20 million tons of highquality fly ash for concrete production.

Dry triboelectrostatic separation can effectively remove carbon from fly ash. This paper will discuss the principle and potential of using a dry triboelectrostatic separation process for fly ash beneficiation. Results from laboratory experiments on several fly ash samples from operating power plants will

concrete block plants, quarries, import and rail terminals, as well as fly ash production facilities. ST Triboelectrostatic Separation Technology Overview ST utilizes a unique, patented process for separating unburned carbon from the mineral constituents of coal combustion fly ash. In the ST separator (Figure 1), material is fed into the

WhatsApp)

WhatsApp)