iron ore mining process flow chart YouTube

#0183;#32;This video is unavailable. Watch Queue Queue. Watch Queue Queue

WhatsApp)

WhatsApp)

#0183;#32;This video is unavailable. Watch Queue Queue. Watch Queue Queue

Iron ore mining process flow chart. From the iron ore processing flow chart photograph, we can see the flat iron ore process flow will go as follow:Raw iron ore is skyrocketed in the iron ore mines to start with Then will feed iron ores to the iron ore major crusher crushing cavity, in which large size natural iron ore will be resized into iron ore sand...

Iron ore beneficiation process flow Raw grade of iron ore: % Iron concentrate grade: % Yield: % Crushing equipment: crusher30mmJaw crusher crusher 10mmCone crusher Grinding equipment:

When the iron ore is extracted from the mine, it must undergo several processing stages. Six steps to process iron ore 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crushers CSS before the crushing stage. A static screen is used to divert...

process flow chart for iron ore beneficiation plant. Flow Chart Iron Sand Mining Process. Iron ore mining process flow chart is a hightech enterprise involved in research and development production sales and serv as well In the past 20 years we are committed to the production of mining equipment sand making equipment industrial mill provide highway rail way and water

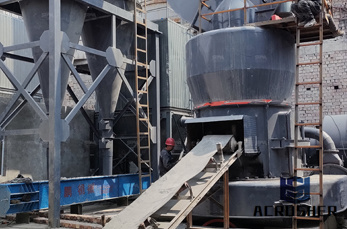

Iron Ore Mining Process Flow ChartIron Ore Mining Machine. Iron ore mining process For iron ore mining processs crushing when the first treatment When grinding the material into the grinding chamber by the shovel blade into the grinding roller and grinding ring between RCC RCC after the powder with the blower circulating wind machine qualified with the powder gas inflow whirlwind powder which

Iron ores are rocks and minerals from which metallic iron can be economically extracted. The ores are usually rich in iron oxides and vary in color from dark grey, bright yellow, or deep purple to rusty red. The iron is usually found in the form of magnetite, hematite, goethite, limonite or siderite. Ores containing very high quantities of hematite or magnetite are known as quot;natural orequot; or quot;direct shipping orequot;, meaning

Multotec''s Iron Ore Industry Flow Sheet. We use cookies to improve your experience on our website. By using our site you agree to Cookies Policy

Iron ore is an important raw material for iron and steel production enterprises. After crushing, grinding, magnetic separation, gravity concentration etc, gradually we can get iron from natural minerals (iron ore). It is the mineral aggregates that contain iron or

#0183;#32;Iron processing, use of a smelting process to turn the ore into a form from which products can be in this article also is a discussion of the mining of iron and of its preparation for smelting. Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive magnetic properties. It constitutes 5 percent by weight of the Earths crust, and it is the

Iron Ore Mining Process Flow Chartiron Ore Mining. Iron ore mining process flow chart because of space limitations only the iron ore milling process to brief you if you want a more specific understanding of the iron ore mining process and detailed iron ore mining process flow chart please contact our customer service they will be detailed to

Iron Ore Mining Process Flow Chart Flowcharts Pdf Flowchart Software is a program used to draw diagrams in a type of a flowchart which is made up of boxes and arrows The Flowchart Software is also used to design and document simple processes as well as visualizing the process and helping users to better understand a process.

WhatsApp)

WhatsApp)