Ball Mill 1000 kg YouTube

#0183;#32;Ball Mill 1000 kg for alumina lining. Ball Mill 1000 kg for alumina lining. Skip navigation quot;Denver Ball Millquot; mineral and ore processing by quot;Savona Equipmentquot; Duration: 0:41.

WhatsApp)

WhatsApp)

#0183;#32;Ball Mill 1000 kg for alumina lining. Ball Mill 1000 kg for alumina lining. Skip navigation quot;Denver Ball Millquot; mineral and ore processing by quot;Savona Equipmentquot; Duration: 0:41.

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming

With more than 100 years of experience in ball mill technology, Metsos ball mills are designed for long life and minimum maintenance. They grind ores and other materials typically to 35 mesh or finer in a variety of applications, both in open or closed circuits.

Jul 5, 2017 BEST PRICE TOP QUALITY Laboratory Mill Ball Mill 1 kg by BEXCO BRANDFREE DHL

quot;Denver Ball Millquot; mineral and ore processing by quot;Savona YouTube 18 Dec 2012 This fully restored 3 x 5 Denver Ball Rod MIll is rubber lined and spout Mill 100 kg. by pscmceramic 3,024 views #183; Thumbnail 2:19

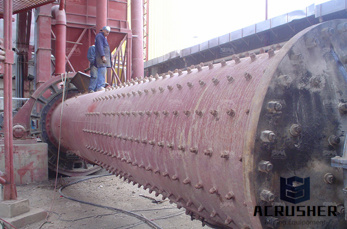

Ball Mills Steel Ball Mills amp; Lined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800s. The basic construction of a ball mill is a cylindrical container with journals at its axis.

Bionics Scientific is a leading laboratory ball mill manufacturers in India and offers its customers a fair deal in buying ball mills with facilities of customized size and capacities up to 10 Kg. In standard, these lab scale ball mill machines come in 2Kg, 5Kg and 10 Kg and are sold all over India at highly competitive price. These machines are supplied with steel grinding balls with

ball mills denver, ball mills aaa manufacturing, inc. 6ft x 10ft ball mill. qty. type. id . description. 1, ball, gm040, 6 ft x 10 ft denver ball mill, this ball mill is complete with 200 hp motor, 4,160 volts, faulk

#0183;#32;Ball Mill 1000 kg for alumina lining. [Hindi] Ball Mill, Hammer mill amp; Critical speed of ball mill, Grinder || Chemical Pedia Duration: 12:34. Chemical Pedia 25,062 views

Laboratory Ball Mill 1 kg TOP QUALITY BRAND BEXCODHL SHIPPING. shipping: + shipping . BEST PRICE Laboratory Ball Mill Motor 2 kg by Top Quality Brand BEXCO DHL Ship. shipping: + shipping . Best Price Laboratory Ball Mill 1 kg TOP QUALITY PRODUCT OF BRAND BEXCO DHL SHIP.

denver ball mill 1 kg. denver ball mill 1 kg . The Denver disc mill had a disc diameter of 200 mm and a capacity of 25 kg/h The Denver ball mill of length 300 mm and diameter 200, as ore particles are forced to make imprints on the liberated metal in response to the forces as presented in Fig 1 c Fig 1, Contact Supplier. Get More

Denver Ball Mill 1 Kg [ 5395 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to help you meet your needs with our equipment, with our distribution and product support system, and the

Denver Ball Mill 1 Kg [ 8749 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to help you meet your needs with our equipment, with our distribution and product support system, and the

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum chunk size, product size as P80 and maximum and finally the type of circuit open/closed

offers 161 denver ball mill products. A wide variety of denver ball mill options are available to you,

The sizing of ball mills and ball milling circuits from laboratory grinding tests is largely a question of applying empirical equations or factors based on accumulated experience. Different manufacturers use different methods, and it is difficult to check the validity of the sizing estimates when estimates from different sources are widely divergent. It is especially difficult to teach mill

#0183;#32;ball mill 100 kg motor gear 2 hp 150 rpm alumina lining

WhatsApp)

WhatsApp)