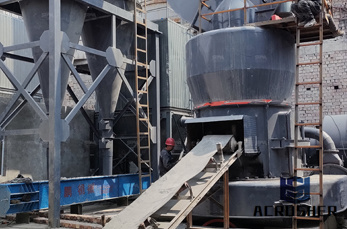

grinding mill process

Grinding Mills Common Types. As the name implies, in the batch mills, Fig., the charge of powder to be ground is loaded into the mill in a batch and, after the grinding process is completed, is removed in a batch.

WhatsApp)

WhatsApp)

Grinding Mills Common Types. As the name implies, in the batch mills, Fig., the charge of powder to be ground is loaded into the mill in a batch and, after the grinding process is completed, is removed in a batch.

The first step in slag processing is size reduction to liberate metallic iron and ironbearing minerals. This is done by crushers or by autogenous grinding, that is, the slag is ground on its own in the grinding mill without any balls. The latter process yields higher quality product as the iron product discharged from grinding mill contains as high as 80% Fe (Shen and Forssberg, 2003).

Ball Mill, Grinding Mill, Ball Mill Manufacturers, Xinhai grinding mill has excellent energy saving ability, Xinhai, as ball mill manudactures, the energysaving ball mill up to 30%, great ball mill working principle, which . view more; Rolling of Metals: Process and Principles (With . The rolling process is shown in Fig. : Rolling is done both hot and cold.

Get grinding mill in rolling prcess Price. You can get the price of grinding mill in rolling prcess and a Aamp;C representative will contact you within one business day. Grinding Mill an overview | ScienceDirect Topics. The first step in slag processing is size reduction to liberate metallic iron and ironbearing minerals. This is done by

No studio is ever complete without a solid rolling mill. Whether you want to roll wire, reduce the thickness of sheet metal, or simply get creative with pattern im, youll need one of the best rolling mills for jewelry to get the job done.

Hot rolling is a metalworking process that occurs above the recrystallization temperature of the material. After the grains deform during processing, they recrystallize, which maintains an equiaxed microstructure and prevents the metal from work hardening. The starting material is usually large pieces of metal, like semifinished casting products, such as slabs, blooms, and billets.

23/12/2018#0183;#32;The grinding process has the least material removal rate among other machining processes because of the following reasons Size effect: As above discussed the machining is done by the abrasive action of grinding wheel thats why a large portion of the abrasive will be embedded inside the wheel and a small portion of abrasive will be allowed to interact with them, therefore, less material

Recommended grinding mill in rolling prcess. Rolling (metalworking) Wikipedia. Hot rolling is a metalworking process that occurs above the recrystallization temperature of the material. After the grains deform during processing, they recrystallize, which maintains an equiaxed microstructure and prevents the metal from work hardening.

rolling mills (8 stand roughing rolling mill, 4 stand intermediate rolling mill, and 4 stand finishing rolling mill) was built by MorganSumitomo Heavy Machinery Co. Ltd.. In the 1980s, the aimed quality of products was shifted toward highvalueadded special steel quality, and, to achieve this, in 1986, a threeroll finishing rolling

Pomini Tenova is the worldwide leader in the design and supply of Roll Grinders for flat product Rolling mills as well as of special machines for grinding of heavy components. Roll Grinder Heavy, Medium and Light Duty Fully Automatic CNC Roll Grinders assure superb performance in terms of tolerance and Surface finishing of all type of rolls, high reliability and internationally patented measuring and control

The rolling process is used to made plates, steel sheets, etc. Bearing, Turbines rings are rolling products. Apart from that, in the rolling applications, there are two types of rolling products. Those are as follows: Hot Rolled Products: Hot rolled products are made by a hot rolling process.

Re Rolling Mills Process Flow Chartre Rolling Grinding Machines Process Flow Chart. rerollingmillsprocessflowchartrerollinggrindingmachinesprocessflowchart mill cold rolling mill other secondary mills captive power plants and a host of other analytical methods were followed to improve steel production process in the eaf in order to do so the study was divided into two phases

In fact, roll grinding directly influences the speed of the rolling mill. Due to this, over the years foil rollers have developed grinding strategies capable of maximising rolling speed whilst keeping the desired surface appearance and enhanced surface uniformity. Wear of

grinding mill in rolling prcess As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for anyel sizereduction requirements including quarry, aggregate, and different kinds of minerals.

Vertical Rolling Mill For Coal in israel Vertical roller mill is a kind of grinding machine for cement raw material cement clinker slag and coal slag It has the features of simple structure and low cost of manufacture and use Vertical roller mill has many different forms but it works basically the same All of these forms of machine come with aAs a leading global manufacturer of crushing equipment,

With EAIs Grinding and Rolling Control package, you have total control over your process. Features like auto gap control, bin keep full, and mill optimization keeps your system working hard for you. Our feed mill grinding and rolling control system adapts to any hammer mill

Understanding Rolling Process in Long Product Rolling Mill Steel rolling consists of passing the material, usually termed as rolling stock, between two rolls driven at the same peripheral speed in opposite directions ( one clockwise and the second anticlockwise) and so spaced that the distance between them is somewhat less than the thickness of the section entering them.

The impact of this is the largest of any rolling process. In fact, roll grinding directly influences the speed of the rolling mill. Due to this, over the years foil rollers have developed grinding strategies capable of maximising rolling speed whilst keeping the desired surface appearance and

Rolling Mills About STProjects By many years of experience of its employees Projects has developed itself to a full supplier for the process industry, with as specialisation components and installations for the treatment of dry substances and fluids.

WhatsApp)

WhatsApp)