Ball Mill Design/Power Calculation

#0183;#32;Ball Mill Power Calculation Example. A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing #188; inch (6350

WhatsApp)

WhatsApp)

#0183;#32;Ball Mill Power Calculation Example. A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing #188; inch (6350

The rod mill work index laboratory test is conducted by grinding an ore sample prepared to 80% passing mm (#189; inch, the original test being developed in imperial units) to a product size of approximately 1 mm (in the original and still the standard, 14 mesh; see Chapter 4 for definition of mesh), thus determining the rod mill work index (Wi R or RWi).

The mill product can either be finished size ready for processing, or an intermediate size ready for final grinding in a rod mill, ball mill or pebble mill. AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball mill.

Grinding in small plants, as in larger installations, has proven to be the most costly of all unit operations from both capital and operating standpoints. Therefore, grinding deserves the most scrutiny of all operations during the design procedure. A recent survey by a major grinding mill manufacturer reveals that more than 80 autogenous or semiautogenous mills having between 100 and 1,000

Bond Ball Mill Work Index, BWi, kWh/t Bond Rod Mill Work Index, RWi, kWh/t Table 1. Example of AG/SAG Ball Mill Circuit Wio Calculations [1] [2] ABstrAct Optimum use of power in grinding, both in terms of grinding efficiency and use of installed capital, can have a large effect on profitability. Mill operators have long used operating

rod mill work index classification Grinding Mill China. rod mill work index classification [ 4383 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to help you meet your needs with our equipment, with our distribution and product support system, and the

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

Abstract: The Bond work index is a measure of ore resistance to crushing and grinding and is determined using the Bond grindability test. Its value constitutes ore characteristic and is used for industrial comminution plants designing. Determining the Bond work index value is

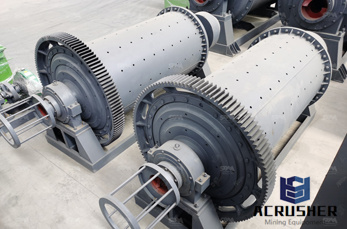

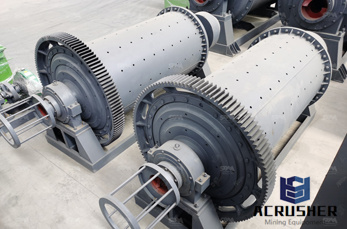

Our mills are as varied as the requirements of our customers. Ball mills, vertical mills, compact mills, jet mills or roller mills? Our employees are experts in the field of grinding plants, and they analyze for you just which mill will provide you with the most efficient production process possible.

Metallurgical ContentBasic EquationsSize Distribution and Exposure RatioEquations for Work Index VariationsWork Index and Crack Energy What is the Bond Work Index FormulaEquation? In case you had forgotten, here is a classic: You can read all the details of this now Biblical grinding power requirement calculation formula in Fred Bonds original paper. You can also review the stepby

Stone crushing plant mainly consists of vibrating feeder, jaw Crusher, impact crusher, vibrating screen, belt conveyor, centralized electronic control components, and the designed production capacity is 50800t/h. rapid determination of bond rodmill work index by modeling the grinding kinetics.

correlation between the abrasion value(X2) and work index (Wi) is found to be Wi = Ln (X2) + with correlation coefficient of KEYWORDS: Bond work index #177; Mechanical properties of rocks #177; Grinding energy Crushing resistance 1 INTRODUCTION Comminution in a mineral processing plant, or mill, involves a sequence of crushi ng

3d animation istanbul, 3d modeling and design, plant animation, machinery animation, machine working running animations 3d animasyon istanbul, 3d modelleme...

#0183;#32;For the grinding plant treated here, they are: FTR =, and F~ = Global operational work index for the complete plant A global operational work index Wiog will be defined for the plant shown in Figure 1, assuming a unitary ball mill circuit equivalent (, having one ball mill).

SAG MILL TESTING AN OVERVIEW OF THE TEST PROCEDURES AVAILABLE TO CHARACTERIZE ORE GRINDABILITY AUTHOR: VERRET, G. CHIASSON AND A. MCKEN SGS KEYWORDS Comminution, grindability, grinding, SAG mill, AG mill, milling, HPGR, work index, pilot plant INTRODUCTION The resistance of ore samples to breakage (or hardness) is measured

Learn about vertical grinding mills and coal pulverizers! We look at all of the vertical grinding mills main components, how it works and some of its design...

WhatsApp)

WhatsApp)