D. Touil''s research works | University of Science and

Dry grinding experiments on cement clinker were carried out using a laboratory batch ball mill equipped with torque measurement. The specific energy was found to be dependent on operating

WhatsApp)

WhatsApp)

Dry grinding experiments on cement clinker were carried out using a laboratory batch ball mill equipped with torque measurement. The specific energy was found to be dependent on operating

Grinding of clinker is the last and most energyconsuming stage of the cement manufacturing process, drawing on average 40% of the total energy required to produce one ton of cement.

#0183;#32;In the cement industry, the clinker grinding step consumes about onethird of the power required to produce one ton of cement. This refers to an average specific power consumption of 57 kWh per ton [1]. Such large amounts of energy justify the need to

Energy efficiency of cement finish grinding in a dry batch ball mill. Author links open overlay panel D. Touil a S. Belaadi b C. Frances a. Show more

Energy efficiency of cement finish grinding in a dry batch ball mill_ 385|36. Energy efficiency of cement finish grinding in a dry batch ball mill_

#0183;#32;Typical specific energy consumption is 30 kWh/t in grinding of cement. Barmactype crushers found application as a pregrinder in cement grinding circuits operating with ball mills to reduce the specific energy consumption of ball millgrinding stage [ 2 ].

The Department of Energy''s Office of Scientific and Technical Information Energy efficiency of cement finish grinding in a dry batch ball mill (Journal Article) | skip to main content

V. Energy Efficiency Improvements to Reduce GHG Emissions C. Energy Efficiency Improvements in Finish Grinding MMBtu/ton of cement Wet Long Dry Preheater Preheater/Precalciner Source: EPA, 2007a (Table 33)

grinding mill power calculation Popular Education. In this paper, a new approach for the calculation of the power draw of cement grinding ball mills is proposed for this purpose, cement grinding read more calculation of the power draw of dry multicompartment ball mills modeling the specific grinding energy

energy efficiency of cement finish grinding in a dry batch ball mill. Energy efficiency of cement finish grinding in a dry batch ball mill; prev. next. out of 6. Post on 26Jun2016. 214 views. Category: Documents. 0 download. Report. Download; Facebook. Twitter. E

energy efficiency of cement finish grinding in a dry batch ball mill. Energy efficiency of cement finish grinding in a dry batch ball mill; prev. next. out of 6. Post on 26Jun2016. 214 views. Category: Documents. 0 download. Report. Download; Facebook. Twitter. E

Finish Grinding Figure 2: Rotary Cement Kiln (Dry Process with Cyclonic Preheaters).. 4 Figure 3: Schematic Improving Thermal and Electric Energy Efficiency at Cement Plants: International Best Practice 1 Cement production is a resourceintensive practice involving

Finish Grinding Energy efficiency measures in dry process cement plants..... 87 Table 9. Energy efficiency measures The production of cement is an energyintensive process. Typically, energy consumption accounts for 2040% of production costs.

Energy efficiency of cement finish grinding in a dry batch ball mill. Dry grinding experiments on cement clinker were conducted using a laboratory batch ball mill equipped with torque measurement. Specific energy was found to be dependent on operating parameters and clinker environment. Additional compounds such as gypsum and pozzolanic tuff improve energy efficiency.

Clinker cooler and finish grinding Energy efficiency measures and reductions in CO2 emissions Figure 10: Capacity installed by technology and age The Dry category includes preheater kilns, kilns with preheater and precalciner and dry long kilns.

#0183;#32;There are efficiency factors for dry grinding, open circuit ball milling, mill diameter, oversize feed, grinding finer than 75 microns and too large or too small reduction ratios. For cement application, the dry grinding (EF1), mill diameter (EF3), oversize feed (EF4) and fine product (EF5) factors are relevant.

Touil D., Belaadi S. y Frances C., Energy efficiency of cement finish grinding in a dry batch ball mill. Cement and Concrete Research 36 416421 (2006). [ Links ] Touil D., Belaadi S. y Frances C.,The specific selection effect on clinker grinding efficiency in a dry batch ball mill.

Energy efficiency of cement finish grinding in a dry batch ball mill, Cement and Concrete Research, volume 41, issue 3, pp. Automation and optimization of coal grinding by means of ball mills

Dry grinding experiments on cement clinker were carried out using a laboratory batch ball mill equipped with torque measurement. The specific energy was found to be dependent on operating parameters and clinker environment. Additional compounds such as gypsum

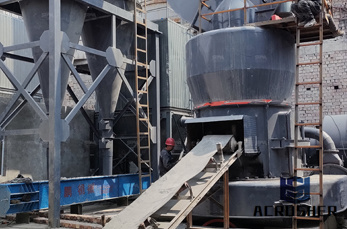

In the cement pre grinding system, the general trend in the use of roller press or specially used for grinding mill stand as a pre pre grinding, then the composition of grinding system with ball mill, this combination of high grinding efficiency, energy saving and had no effect on the quality of cement.

WhatsApp)

WhatsApp)